How to Dry Filament

Drying filament can be an excellent solution to improve print quality. In this article, you will learn how to dry filament and how to store it after drying.

Honestly, I never had to dry plastic before. I hadn’t encountered any issues with it previously, but that was probably because I quickly went through my spools. Now that I have about 40 spools of various filaments stored without proper care, I've started to notice a decline in print quality with the older spools.

After drying them, the print quality returned to what it was when I first started using a new spool, so I thought it would be helpful to share my findings with you.

Why Dry Plastic?

The main reason for drying filament is to achieve more stable results during printing. Most filaments used in 3D printing are hygroscopic, meaning they absorb moisture fr om the air and lose some of their properties.

Some filaments (PETG, PC, ABS, and nylon) are more hygroscopic than others (PLA), and it’s recommended to dry them before starting a new print to achieve the best print quality.

How to Tell if Your Filament Needs Drying?

If your filament has absorbed moisture, you will hear a characteristic crackling sound during extrusion.

I recommend first heating the nozzle to the appropriate temperature (depending on the filament being used) and extruding 100 mm of filament. If you hear small pops, crackling, hissing sounds, or notice steam coming from around the nozzle during extrusion, it means the filament needs to be dried.

The moisture contained in the filament quickly turns into steam during extrusion and can cause problems during printing.

The tension becomes more noticeable

In most cases, tension is the first sign that the filament needs to be dried. I’ve read many reports online wh ere users achieved high-quality models with a certain brand of filament, but after a few months, they struggled with tension issues. I encountered similar problems with an old spool of PETG, which initially printed well, but after six months, it became impossible to print.

After drying the filament, tension issues should be significantly reduced or even eliminated (if retraction settings are properly adjusted).

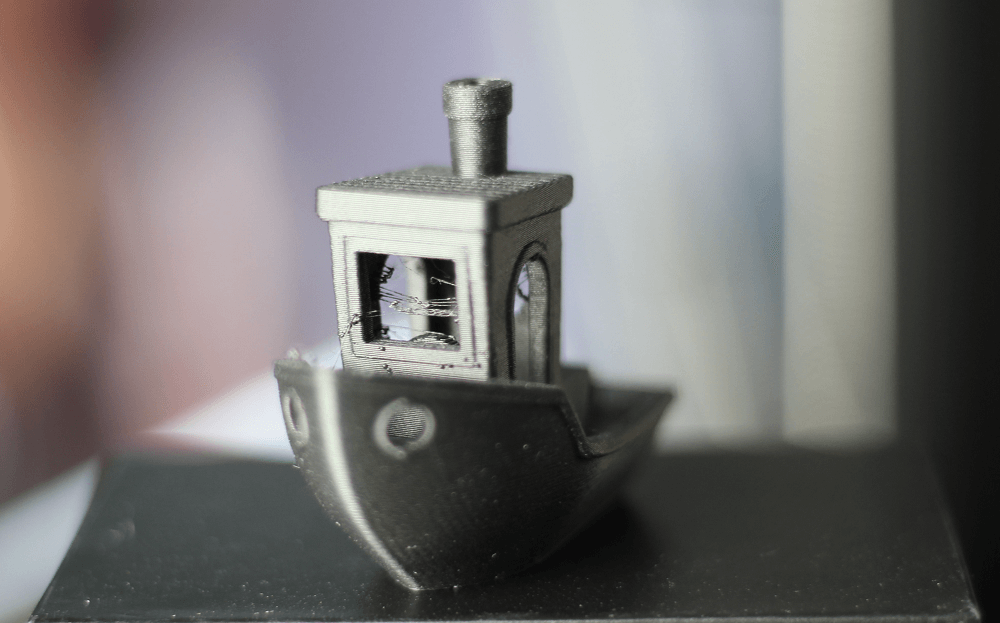

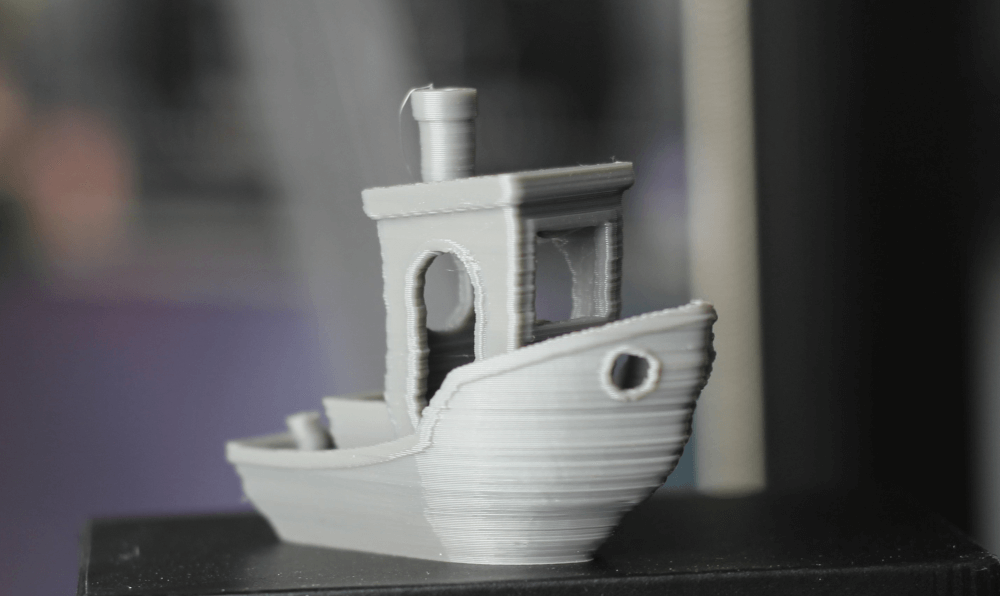

Inconsistent Extrusion

Another way to determine if your filament has absorbed moisture is through inconsistent extrusion with misaligned layers.

In most cases, when filament absorbs moisture, it does so unevenly, causing some sections of the filament to retain more moisture than others. When this water is released during extrusion, the pressure inside the nozzle increases slightly, leading to an extrusion of more plastic for a brief period. This results in your layer lines being inconsistent, and the finished models may appear to have poor quality.

Additionally, the filament tends to swell when it absorbs moisture, so instead of the usual diameter of 1.75 mm, your filament may measure 1.8 mm in certain areas, resulting in poor extrusion quality.

The filament is brittle and breaks easily

PLA often exhibits breaks and brittleness because when it absorbs moisture, the filament loses some of its flexibility. I haven't experienced brittleness with other types of filaments, but your results may vary.

After drying, the filament should regain some flexibility, making it harder to break.

Necessary Conditions for Drying Filament

To effectively dry and remove moisture from the filament, you need a device that isolates the filament while simultaneously increasing the temperature in a controlled manner.Oven

Using an oven is the simplest and most effective way to dry filament. However, this is only feasible if you have an oven that allows for precise temperature control.

Before placing the filament in the oven, it’s important to check the accuracy of the oven’s thermostat. Take a regular thermometer and place it in the oven after preheating to check the internal temperature. Ensure that the temperature inside the oven matches what you have set. Adjust accordingly if there are discrepancies.

I use an infrared thermometer for this purpose. I noticed that when I set the oven to 50°C, the temperature inside was around 45°C, so I had to increase it a bit to compensate.

Some ovens are not very accurate, and when drying PLA, you can easily ruin the filament if the temperature inside the oven exceeds safe limits, even if only for a few minutes.

Dehydrator

Another popular option for drying filament is a food dehydrator. There are many guides online on how to convert a food dehydrator into a filament dryer.

The main drawback of using a food dehydrator is its capacity. You can only dry one or two spools of filament at a time, depending on the size.

You can find a cheap food dehydrator at a local store or on eBay/OLX. Since you’ll be using it solely for drying filament, it doesn’t necessarily need to be a brand-new machine.

Filament Dryer

I’m not a big fan of filament dryers because, in my opinion, they are a bit expensive, considering that you can only dry one spool at a time. However, it can be a good investment if you frequently print with nylon or PETG, as you can feed the filament directly into the printer from the dryer. This way, the filament remains dry until it reaches the nozzle and is extruded.

Drying Temperatures for Filament

PLA

PLA (or Polylactic Acid) is the most popular filament used for 3D printing because it is easy to print and does not require special preparation.

My experience with PLA has been quite good. I have encountered only a few clicks with a spool of green PLA that had not been used for over a year.

How to Dry PLA?

PETG

PETG (or Polyethylene Terephthalate Glycol) is currently a popular alternative to ABS filament because it offers higher thermal resistance while being easier to print.

For me, PETG has been the filament that absorbed the most moisture, resulting in several failed prints.

In most cases, the tension was terrible, and the layer lines, after the plastic cooled, looked poor.

How to Dry PETG?

I recommend drying PETG at a temperature of 60-65°C for at least 4 hours.

ABS

ABS (or Acrylonitrile Butadiene Styrene) was the most popular filament used at the dawn of the 3D printing era. It is still in use today because of its good thermal resistance, but it does have some drawbacks. Reliable printing typically requires an enclosed printer and good ventilation due to the odor and toxic fumes it emits.

My experience with ABS has been relatively positive, and I haven’t found it necessary to dry the spools before printing.

How to Dry ABS?

TPU

TPU (or Thermoplastic Polyurethane) is the most popular filament for RC enthusiasts because it can be used to print semi-flexible models.

Whenever I leave my TPU for a couple of months, I start experiencing a lot of stringing and inconsistent extrusion. After a few hours of drying, the difference in quality is huge.

How to Dry TPU?

Nylon

Nylon is one of the most hygroscopic materials you can print with. It is recommended to dry the spool before each print because as soon as you take it out of the package, the filament starts absorbing moisture.

For the best results, I suggest making a spool holder that isolates the filament during printing or using a filament dryer.

How to Dry Nylon?

ASA

ASA (or Acrylonitrile Styrene Acrylate) is similar to ABS but offers better UV resistance, making it an excellent choice for 3D printed parts intended for outdoor use. It has improved resistance to stress cracking and, in my opinion, is somewhat easier to print with.

How to Dry ASA?

For me, ASA was no different from ABS. I have never felt the need to dry an ASA spool before printing, but your results may vary.

I recommend drying ASA at a temperature of 80-85°C for at least 4 hours.

PC

PC (or Polycarbonate) is primarily used in engineering applications because parts printed from PC are strong and rigid. Printing with PC can be challenging without proper pre-drying of the material. It is as hygroscopic as ABS, PETG, or nylon.

Polycarbonate is recommended to be dried before each print and stored in an airtight container when not in use.

How to Dry PC?

How to Store Dried Filament?

After drying the filament, it's essential to store it in a dry place with low humidity. I keep my spools in closed cabinets with several silica gel packets inside. This works well for me because I don’t have high humidity in my workshop.

If you live in a high-humidity area, I recommend storing the spools separately in airtight bags. This way, you'll keep the filament dry longer, but you won't be able to print without taking the spool out of the bag.

If space isn’t an issue, purchasing an airtight plastic container and turning it into an insulated filament holder is likely the best way to avoid moisture getting into the filament. It requires some effort, but ultimately, this solution will save you from the hassle of constantly drying the filament.

Conclusion

Now you have a better understanding of how to dry filament for optimal print quality.

If you're still experiencing issues while printing, you may need to perform calibration. Check out the 3D Printer Calibration Guide using the IdeaMaker article, which will guide you through the entire process.

- Комментарии