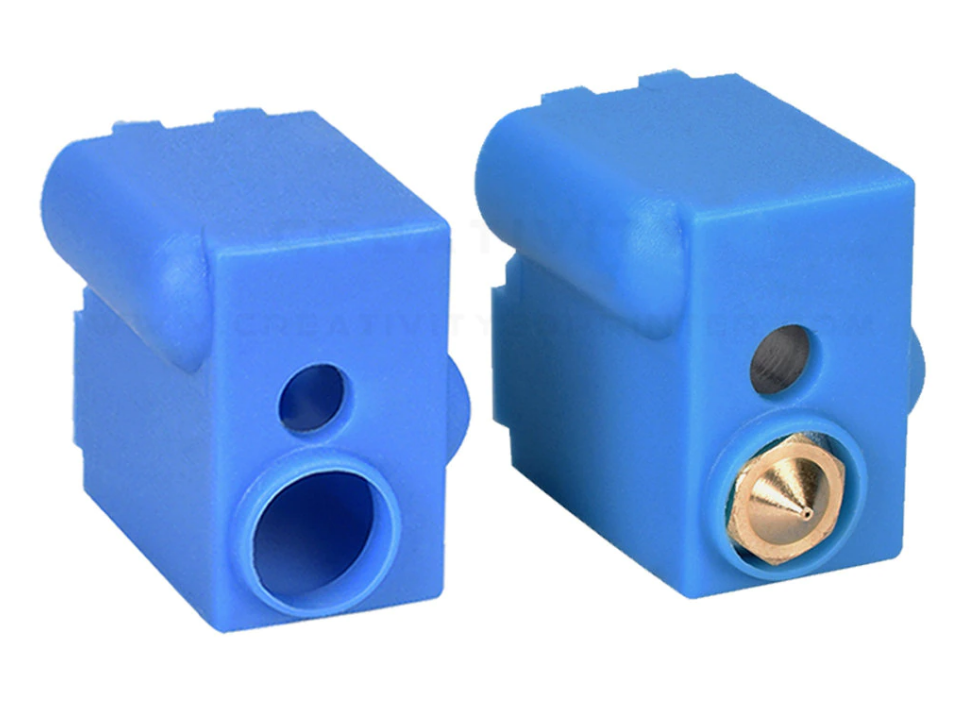

Silicone Covers for Heating Block (Silicone socks)

The heat-resistant silicone material with a non-stick coating helps prevent the buildup of residue and the adhesion of hardened plastic to the heating element.

|

50 UAH

|

In stock

|

-

+

|

|

|

|

78 UAH

|

In stock

|

-

+

|

|

|

|

78 UAH

|

In stock

|

-

+

|

|

|

|

78 UAH

|

In stock

|

-

+

|

|

|

|

78 UAH

|

In stock

|

-

+

|

|

|

|

99 UAH

|

Out of stock

|

|

|

|

|

|

Out of stock

|

|

|

|

|

|

Out of stock

|

|

|

|

|

|

Out of stock

|

|

|

|

|

78 UAH

|

Out of stock

|

|

|

History of the Silicone Cover

Silicone covers for the heating element of FDM 3D printers are now commonly found on models from many manufacturers. However, until recently, silicone covers were not used; heating blocks were either left uncovered or fitted with coverings made from other materials.

The absence of a protective cover on the heating block in early 3D printer models led to numerous issues. Firstly, the constant high temperature from the heating element and nozzle, combined with plastic vapors, caused the heating block to accumulate soot, requiring frequent cleaning. Another problem was the adhesion of hardened plastic, which could significantly affect print quality and even lead to model failure. The adherence of plastic to the metal heating block made removal a real challenge. Once the plastic was removed, scratches and abrasions remained on the surface of the heating block, causing even more plastic to stick.

The lack of a protective silicone cover also resulted in increased energy consumption for the 3D printer. Heat from the heating block dissipated into the air, forcing the heating elements to work harder to maintain the desired temperature, leading to higher energy costs.

Using protective covers made of metal or plastic partially addressed these issues. Energy consumption decreased, and the heating block was protected from plastic and soot; however, the covers themselves suffered. Soot and plastic adhesion transferred to the covers, requiring frequent replacements.The introduction of silicone covers for heating elements fully resolved these problems.

Advantages of Silicone Covers

The primary purpose of silicone covers for the heating block of a 3D printer is to stabilize temperature while preventing soot buildup and plastic adhesion.

Advantages of silicone covers include:

- Reduction in energy consumption due to maximum heat retention and stabilization of the heating block temperature.

- Protection against plastic adhesion and soot buildup on the nozzle and heating block.

- Enhanced protection for the printed model from the heating block's temperature.

- The ability to use more intensive cooling for parts without worrying about drops in temperature at the nozzle.

Despite their effectiveness, silicone covers do have a limited lifespan, though it is quite extended. If you notice soot buildup, plastic adhesion, or if the cover is torn, it should be replaced. Do not attempt to substitute silicone covers with those made from other materials, as this will only worsen the situation

Buy Silicone Covers for Heating Blocks

We offer the largest selection of silicone covers for heating blocks in Ukraine, compatible with all popular models of 3D printers, including:

- Silicone cover for MK7/8/9

- Silicone insulation for Volcano (for capsule)

- Silicone cover for E3D V6 1.0

- Silicone cover for E3D V6 (for capsule)

- Silicone cover for CR-10 heating block

- Silicone cover for Sidewinder X1 Volcano heating block

- Silicone cover for E3D V6 with RT100 thermistor